Design and Construction

Patented infill exceeds 6 pounds per square foot

The washed silica sand does not break down from use or heavy traffic. The cryogenic rubber is recycled rubber, frozen and shattered, creating smooth-sided spherical particles. As compared to 3 pounds of ambient rubber found in most other artificial turf, each square foot of FieldTurf contains 4 pounds of silica sand plus 2 pounds of cryogenic rubber. A base layer of silica sand is followed by up to 21 individual layers of mixed silica sand and cryogenic rubber and then topped with a final layer of specially graded cryogenic rubber which stays on the top of the infill system.

FieldTurf is the only system that uses sand and rubber in a «layered» design for quick cut and plant, speed and stability. FieldTurf is never spongy or soggy like «all-rubber» turf systems and provides a high rate of «energy restitution.» This exclusive infill provides superior safety, grass-like stability and better long-term resilience. FieldTurf does not require a separate shock pad to be "In the Safety Zone." Its shock attenuation rating and G-max are similar to the best natural grass systems in use today.

Many tests have been done on the FieldTurf system by organizations at every level concluding that FieldTurf is without a doubt, the safest turf on earth. Ask your FieldTurf Representative for more details.

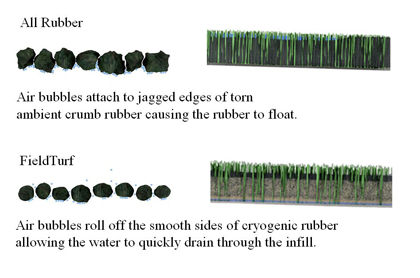

Cryogenic Rubber

Cryogenic rubber is rounded and does not attract microscopic bubbles of air. As a result it does not float nor displace in high use areas. Ambient rubber is jagged, floats and moves with the water flow, migrating to the edges of the field.

Open Fiber Matrix

Design engineering allows cleats to penetrate the fiber surface, twist and release. Superior traction allows athletes to dig and cut, yet provides minimal motion-related injury exposure. Torsional release co-efficiency similar to grass.

Monofilament Fiber Technology

Most turf companies use a variety of fiber manufacturers and their clients seldom know for sure what fiber they will end up getting. Not so with FieldTurf. Our fields have been made with the same fiber - exclusive to FieldTurf - for over 10 years and no other fiber has passed this «test of time». Whether clients purchase the FieldTurf Classic series with our slit film fiber, or the FieldTurf Monofilament series, the supply of such a critical component will never be modified. All of FieldTurf's fibers can be produced in colors to match an endzone or logo requirement.

'FieldTurf Duo' combines four spined monofilament fibers, with four softer rectangular monofilament fibers. Created with the most advanced technology and twisted together in a patent pending design, the result is a unique eight-part fiber pile. FieldTurf Duo's spined fibers remain upright and contribute to superior aesthetics and playing properties, while the softer, flat fibers lay over to encapsulate and stabilize the infill. Exhaustive bio-mechanical testing confirmed that Duo matches up so closely to the playing characteristics of good natural grass that players rarely notice the difference. And because Duo is made of «true» monofilament fiber, loaded with UV inhibiters and shaped in a manner to resist even the heaviest foot traffic, the system will last even longer.

The 'FieldTurf Duraspine' fiber is based on similar structures found in nature. The arched profile features a durable «spine» which runs vertically through the center of each fiber. Like the center stem or vein on a blade of grass, this spine gives each fiber unmatched «memory» and thus resistance to matting. This system also enhances ball-roll properties, bio-mechanics and aesthetics. DuraSpine is extruded through a spinneret, and as a «true» monofilament fiber - not a flimsy slit tape like competing systems - delivers unmatched durability, especially resistance to wear. Tests indicate the DuraSpine fiber is far more resistant to UV and foot traffic, the two main enemies of any turf system. Unlike some new fibers on the market, DuraSpine is not abrasive to players but is silky and lush just like nature intended.

'FieldTurf Classic', featuring the best of the original slit film technology, polyethylene is extruded in sheets and slit into individual fibers, each cut with a unique interior honeycomb pattern. The fibers are then twisted and tufted into the backing. As the infill material is brushed into the system, the honeycomb in each fiber opens below the surface, filling with the tiny sand and rubber granules. In the final stages of infilling the tips of the fibers are split open and lay over to encapsulate the infill. This original invention is what began FieldTurf's revolution of the industry over a decade ago. With over 1500 FieldTurf Classic fields in the ground, over 100 are entering their 8th year of continuous use without any loss of performance.

Superior Surface Stability

FieldTurf is a very stable, uniform, predictable system preferred by elite athletes. The world's #1 brand of artificial turf does not contribute to leg fatigue, ankle injuries, ACL and other problems associated with unstable, rubber-filled turf systems.

In terms of playability, ball roll, safety, aesthetics, and durability - there is no surfacing system on the planet that outperforms FieldTurf. Stringent testing procedures have been performed on FieldTurf with surprising results to natural grass enthusiasts. The FieldTurf system provides the ideal amount of energy restitution necessary for athletes to perform at a high level and is the safest surface for athletic contests.

Stronger, Yet Softer 'Low Abrasion' Fiber

Fiber package used consistently since inception. Very low Abrasion Index, similar to natural grass. Proprietary polyethylene “alloy” fiber engineered specifically for the application.

Sewn Seams

The best all sewn seam system on the market. All sewn seams mean durability at the joints and low maintenance in the future. Our superior installation crews have developed the techniques and are the best in the business.

Backing

The backing is made of a combination of permeable woven and non-woven polypropylene fabrics to provide exceptional strength, stability and unmatched vertical drainage. FieldTurf's fibers are tufted (stitched) into the backing material in rows according to a patented wide gauge spacing formula that enables cleats to penetrate the infill material rather than the surface fiber. This provides excellent traction and very low torsional resistance which prevents injuries. Our patented «finger unit system» adds an impermeable coating over the back of each row of stitching, creating a chemical and mechanical bond for enhanced «tuft bind», leaving the rest of the backing material totally permeable and creating rows of drainage channels.